Hydrogen, as a pollution-free, renewable, and clean energy source, and with its high energy density, is becoming a core development direction in the energy transition process. Hydrogen production by water electrolysis is the mainstream technology for green hydrogen production, and the technological competition between proton exchange membrane electrolyzers (PEM) and alkaline electrolyzers (ALK) has always been a focus of industry discussion. We will conduct a detailed discussion and comparison of the core characteristics of these two technologies.

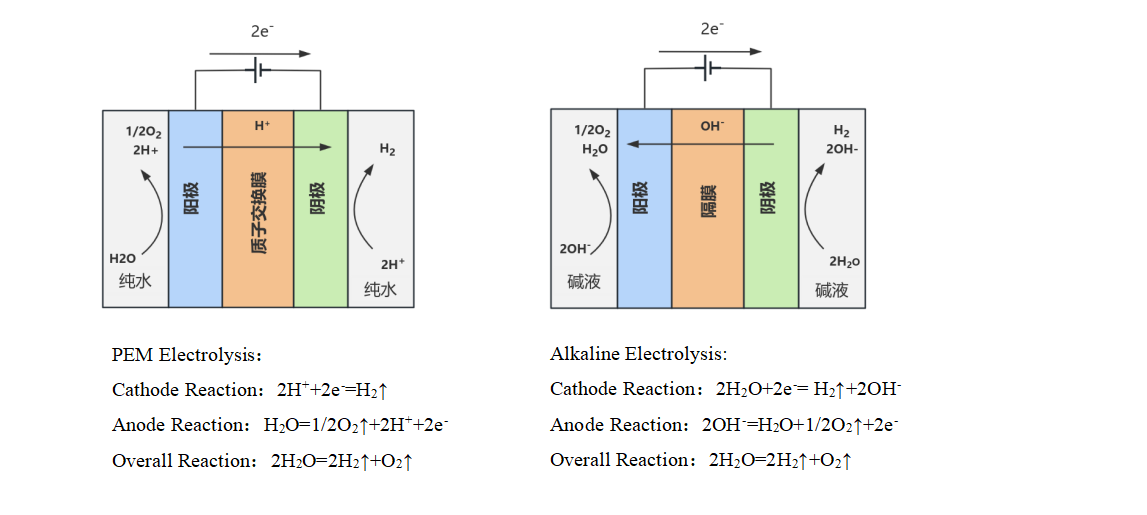

1. Core Principle:

PEM electrolyzer: Uses pure water as the electrolyte and utilizes a proton exchange membrane to conduct hydrogen ions (H + ) and isolate gases. On the anode side, water is used as a reactant for oxidation reaction (OER), generating oxygen (O2 ) and hydrogen ions; under the influence of an electric field, hydrogen ions migrate through the proton exchange membrane to the cathode, where they undergo reduction reaction (HER) to generate hydrogen gas.

Alkaline electrolytic cell: Using a 30% potassium hydroxide (KOH) alkaline solution as the electrolyte, hydroxide ions (OH⁻) are conducted via a diaphragm. .Water molecules on the cathode side gain electrons and undergo a reduction reaction, generating hydrogen gas (H₂ ) and hydroxide ions. Under the influence of the electric field, the hydroxide ions migrate to the anode and undergo an oxidation reaction, ultimately generating oxygen and water molecules. The specific reaction mechanism is shown in the diagram below:

Comparison chart of water electrolysis hydrogen production technologies

Comparison chart of water electrolysis hydrogen production technologies

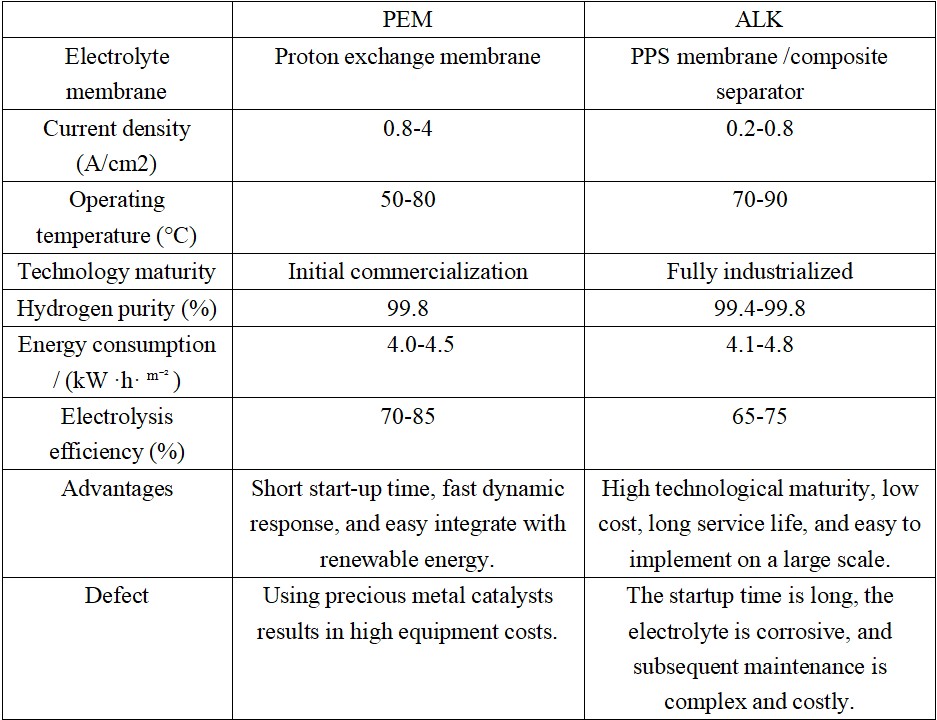

2.Key performance comparison:

The technology comparison table shows that PEM water electrolysis for hydrogen production offers second-level dynamic response speed and wide load adjustment capability, making it adaptable to the intermittent power supply characteristics of wind and solar energy. However, its reliance on precious metal catalysts such as iridium and platinum, and high-performance bipolar plate materials such as titanium alloys, results in high equipment manufacturing costs , limiting its large-scale adoption. Alkaline water electrolysis for hydrogen production, on the other hand, has a high degree of industrialization and has undergone long-term market validation. It requires no precious metal catalysts, resulting in lower overall equipment costs. Furthermore, its long service life makes it easy to achieve gigawatt-scale large-scale applications, making it the current mainstream hydrogen production technology .

3. Structural differences:

PEM and ALK hydrogen production technologies are also reflected in the design and material selection of their components:

3.1 Bipolar plate:

The PEM electrolytic cell electrodes are made of high-performance materials such as titanium plates and pre-coated. A platinum (Pt) coating is applied to the electrode surface to prevent oxidation. The alkaline electrolytic cell bipolar plates are made of carbon steel or pure nickel, welded to the electrode frame, and then nickel-plated. Both types of bipolar plates serve multiple functions, including conductivity, support, and medium transmission.

3.2 Core Components:

PEM electrolyzers are structurally equipped with an additional gas diffusion layer (GDL), using carbon-based materials (such as carbon paper and carbon cloth) for the cathode and titanium-based materials (such as titanium mesh and porous titanium foam) for the anode, precisely controlling the gas-liquid mass transfer balance and optimizing the reaction interface environment. Its core reaction unit—the membrane electrode assembly (MEA)—employs a catalyst-coated membrane (CCM) structure, fabricated through spraying or roll-to-roll coating processes. The process precision of this assembly directly affects the electrolyzer efficiency. In contrast, alkaline electrolyzers do not require a gas diffusion layer; their core process focuses on the matching design of the membrane and electrode.

3.3 Catalysts and Membrane Materials:

The PEM electrolyzer uses iridium (Ir) and its oxides (such as IrO₂ ) as the anode, and platinum-carbon (Pt/C) catalyst as the primary cathode catalyst. The proton exchange membrane is mainly a perfluorosulfonic acid membrane (such as Nafion) to ensure efficient hydrogen ion conduction. The alkaline electrolyzer offers more flexibility in catalyst selection, allowing for the use of noble metals (Pt, Pd, Au, Ag, etc.), transition metals, or carbon-based materials (Fe, Co, Ni, etc.). The membrane primarily uses PPS membranes or composite membranes to ensure effective hydroxide ion conduction and gas-liquid separation .

4. Summary:

PEM electrolyzers, with their rapid response and efficient cleaning, have irreplaceable advantages in distributed green hydrogen projects and renewable energy consumption scenarios, and are the core direction for future technological upgrades; while alkaline electrolyzers, with their mature, stable, and cost-controllable characteristics, will continue to dominate in large-scale industrial hydrogen production and long-term stable hydrogen supply scenarios.

There is no inherent superiority or inferiority among technical approaches; the key consideration is adaptability to the given scenario. Which technical approach do you see as having the most promising future potential?

FAQ:

1、Who are we?

Rubri are based in Anhui, China, start from 2011,sell to Southeast Asia,North America,Eastern Europe,South Asia.

2、What full industry chain services do you offer for alkaline water electrolysis hydrogen production?

Rubri provide full industry chain services including alkaline water electrolysis hydrogen production systems, electrolyzers, gas-liquid separation and purification equipment, plus electrolyzer production lines, installation, replacement and technical guidance.

3、What full industry chain services do you offer for PEM water electrolysis hydrogen production?

Rubri provides various BOP parts and complete systems for the entire process of PEM hydrogen production process.

4、Why should you buy from us not from other suppliers?

Rubri have an experienced professional technical research and development team. Control system matching ability/R&D and quality control ability. Price advantage brought by supply chain integration capabilities.